- The history of laser cleaning technology

- Benefits of using laser cleaning for historical artifacts

- Comparison of laser cleaning with traditional cleaning methods

- The science behind laser cleaning technology

- Different types of lasers used for cleaning historical artifacts

- Laser cleaning as a non-invasive method for artifact restoration

- Challenges in adapting laser cleaning technology for different types of artifacts

- The role of laser cleaning in the restoration of archaeological finds

The history of laser cleaning technology

| Year | Event |

|---|---|

| 1960 | The first working laser is demonstrated by Theodore Maiman. |

| 1970 | Laser cleaning technology is first proposed as a method for removing contaminants from surfaces. |

| 1980 | The first commercial laser cleaning systems are introduced, primarily for industrial applications. |

| 1990 | Laser cleaning technology becomes more widely adopted in industries such as automotive, aerospace, and conservation. |

| 2000 | Advancements in laser technology lead to more efficient and precise cleaning methods. |

| 2010 | Laser cleaning technology continues to evolve, with new applications emerging in fields such as electronics and medical devices. |

Today, laser cleaning technology is used in a wide range of industries, offering a non-contact, environmentally friendly, and highly effective method for removing contaminants from surfaces. From rust and paint removal to delicate cleaning of historical artifacts, laser cleaning has become an indispensable tool for many professionals.

As the technology continues to advance, we can expect even more innovative applications and improvements in laser cleaning technology in the years to come.

#laser #cleaning #technology #history #industrial #applications #advancements #efficiency #precision #innovation

Benefits of using laser cleaning for historical artifacts

Here are some of the :

- Gentle and non-invasive: Laser cleaning is a non-contact method that uses high-energy laser beams to remove dirt, grime, and corrosion from the surface of artifacts without causing any damage.

- Precision cleaning: Laser cleaning can target specific areas of an artifact with pinpoint accuracy, ensuring that only the affected areas are treated while preserving the rest of the object.

- Environmentally friendly: Unlike traditional cleaning methods that use harsh chemicals and solvents, laser cleaning is a clean and eco-friendly process that produces minimal waste and pollution.

- Time-saving: Laser cleaning is a fast and efficient method that can quickly remove years of dirt and grime from historical artifacts, saving time and labor costs.

- Long-lasting results: Laser cleaning can provide long-lasting results, ensuring that historical artifacts remain clean and well-preserved for years to come.

Overall, laser cleaning is a safe, effective, and environmentally friendly method for restoring historical artifacts to their original condition. By using laser technology, conservators can ensure that these precious objects are preserved for future generations to enjoy and appreciate.

Hashtags:

#laser #cleaning #historical #artifacts #preservation

Keywords:

Laser cleaning, historical artifacts, preservation, restoration, conservation

Long-tail phrases:

, gentle and non-invasive cleaning method, environmentally friendly preservation technique

Comparison of laser cleaning with traditional cleaning methods

Traditional Cleaning Methods

- Chemical cleaning

- Mechanical cleaning

- Ultrasonic cleaning

- Steam cleaning

Laser Cleaning

- Uses a high-powered laser beam to remove contaminants

- Does not require chemicals or abrasive materials

- Can be used on a variety of surfaces, including metal, plastic, and glass

- Produces minimal waste

- Is faster and more precise than traditional methods

Comparison

When comparing laser cleaning with traditional methods, several factors should be considered:

- Effectiveness: Laser cleaning is often more effective at removing contaminants than traditional methods.

- Speed: Laser cleaning is faster than traditional methods, making it ideal for high-volume cleaning applications.

- Precision: Laser cleaning offers greater precision, allowing for more targeted cleaning.

- Environmental impact: Laser cleaning produces less waste and does not require the use of chemicals, making it more environmentally friendly.

Overall, laser cleaning is a versatile and efficient cleaning method that offers several advantages over traditional methods. While it may have a higher upfront cost, the long-term benefits make it a worthwhile investment for many industries.

Conclusion

In conclusion, laser cleaning is a superior cleaning method compared to traditional methods in terms of effectiveness, speed, precision, and environmental impact. It is a technology that is likely to continue to grow in popularity as more industries recognize its benefits.

#laser #cleaning #traditional #methods #comparison

#increased #precision #reduced #waste #faster #cleaning #times

The science behind laser cleaning technology

Photothermal interactions occur when a material absorbs laser energy and converts it into heat. This heat causes the material to expand and break apart, allowing the contaminants to be removed. The laser beam can be adjusted to target specific contaminants, making it a highly precise cleaning method.

One of the key advantages of laser cleaning technology is its ability to remove contaminants without the need for harsh chemicals or abrasive materials. This makes it an environmentally friendly and cost-effective cleaning solution. Additionally, laser cleaning can be used on a wide range of surfaces, including metals, plastics, ceramics, and composites.

Another important aspect of laser cleaning technology is its versatility. The laser beam can be adjusted in terms of power, wavelength, and pulse duration to suit different cleaning applications. This flexibility allows for customized cleaning solutions for various industries, such as automotive, aerospace, electronics, and cultural heritage preservation.

In conclusion, the science behind laser cleaning technology is based on the principles of photothermal interactions and laser ablation. This innovative method offers a precise, efficient, and environmentally friendly way to remove contaminants from surfaces. With its versatility and customization options, laser cleaning technology is set to revolutionize the cleaning industry.

- Efficiency

- Precision

- Photothermal interactions

- Laser ablation

- Environmental friendly

- Versatility

- Customization

- #laser

- #cleaning

- #technology

- #photothermal

- #interactions

- #precision

- #efficiency

- #environmental

- #friendly

- #versatility

- #customization

Revolutionary cleaning method, High-powered lasers, Contaminant removal, Precision cleaning, Environmentally friendly solution, Customized cleaning applications

Different types of lasers used for cleaning historical artifacts

1. Q-switched Nd:YAG lasers: These lasers are commonly used for cleaning metal artifacts, as they are highly effective at removing rust, corrosion, and other surface contaminants. They operate at a wavelength of 1064 nm and can be adjusted to deliver short pulses of high energy, making them ideal for precision cleaning.

2. Excimer lasers: Excimer lasers are often used for cleaning delicate materials such as ceramics and glass. They operate at ultraviolet wavelengths, which are highly effective at breaking down organic contaminants without damaging the underlying surface.

3. Fiber lasers: Fiber lasers are versatile tools that can be used for cleaning a wide range of materials, including metals, plastics, and textiles. They offer high precision and control, making them ideal for cleaning intricate or fragile artifacts.

4. CO2 lasers: CO2 lasers are commonly used for cleaning stone and masonry artifacts, as they are highly effective at removing dirt, soot, and other surface contaminants. They operate at a wavelength of 10.6 microns and can be adjusted to deliver a range of pulse durations, making them suitable for a variety of cleaning applications.

In addition to these types of lasers, there are also specialized laser systems that have been developed specifically for cleaning historical artifacts. These systems may incorporate multiple lasers, robotic arms, and advanced imaging technology to ensure precise and effective cleaning.

Overall, laser cleaning offers a number of advantages for cleaning historical artifacts, including:

– Non-contact cleaning: Laser cleaning is a non-contact method, which means that there is no physical contact between the laser and the artifact. This reduces the risk of damage to the surface and allows for precise cleaning in hard-to-reach areas.

– Non-abrasive cleaning: Unlike traditional cleaning methods such as abrasive blasting or chemical cleaning, laser cleaning is non-abrasive and does not require the use of harsh chemicals. This makes it a more environmentally friendly and gentle cleaning method.

– Selective cleaning: Laser cleaning can be highly selective, allowing conservators to target specific areas of an artifact for cleaning while leaving the rest untouched. This level of precision is essential for preserving delicate or intricate surfaces.

In conclusion, the use of lasers for cleaning historical artifacts offers a safe, effective, and precise method for removing dirt and contaminants while preserving the integrity of the object. With a variety of laser types and specialized systems available, conservators have a range of options to choose from when cleaning artifacts.

#laser #cleaning #historical #artifacts

frazy kluczowe:

– Different types of lasers for cleaning historical artifacts

– Advantages of laser cleaning for preserving artifacts

– Specialized laser systems for artifact cleaning

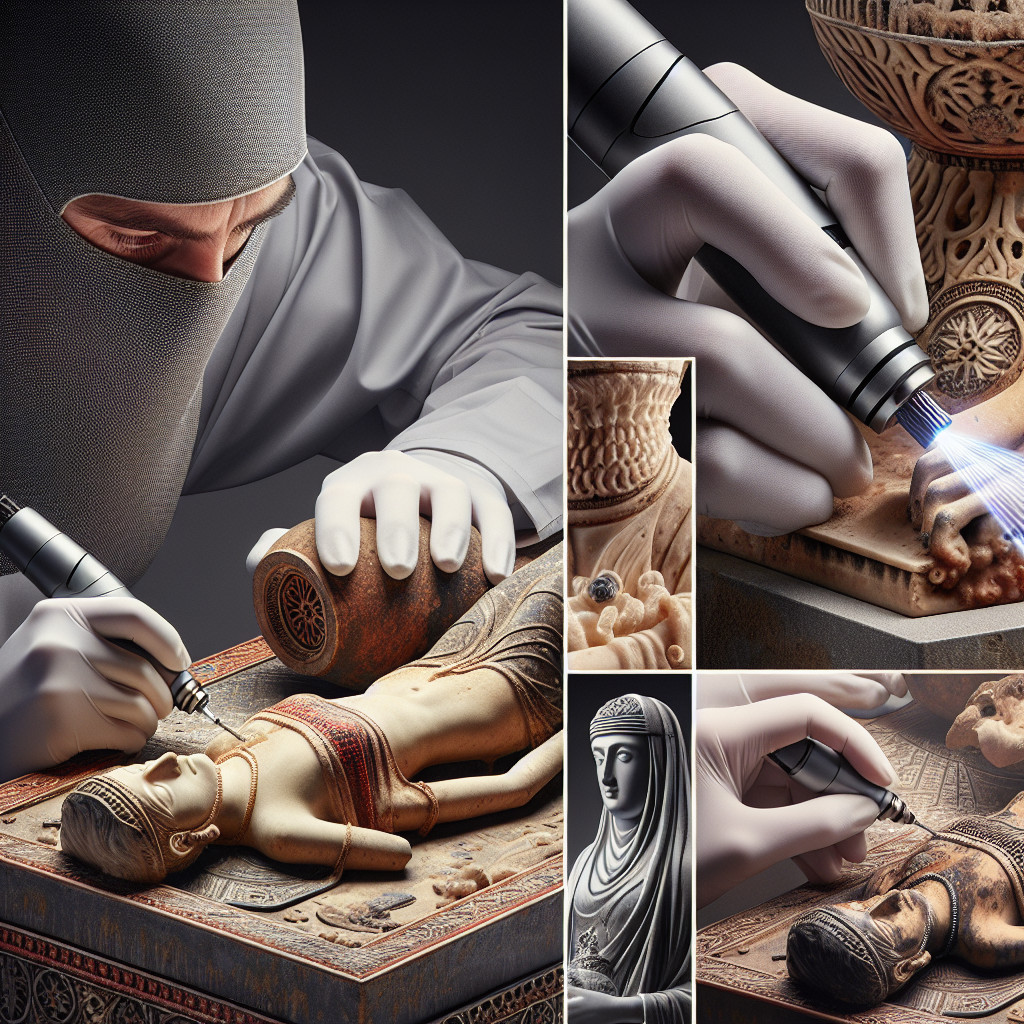

Laser cleaning as a non-invasive method for artifact restoration

Benefits of laser cleaning:

– Non-invasive: Laser cleaning is a gentle and non-destructive method that preserves the integrity of the artifact.

– Precision: Laser beams can be precisely controlled to target specific areas of the object.

– Efficiency: Laser cleaning is a fast and efficient process that can remove contaminants quickly.

– Environmentally friendly: Laser cleaning does not require the use of harsh chemicals or solvents, making it an eco-friendly option.

Applications of laser cleaning:

– Art restoration: Laser cleaning is commonly used to restore paintings, sculptures, and other works of art.

– Archaeology: Laser cleaning can be used to clean and preserve ancient artifacts and archaeological finds.

– Conservation: Laser cleaning is also used in the conservation of historical buildings and monuments.

Overall, laser cleaning is a versatile and effective method for artifact restoration that offers numerous benefits over traditional cleaning methods. By using laser technology, conservators and restoration experts can safely and efficiently restore valuable artifacts for future generations to enjoy.

#artifactrestoration #lasercleaning #culturalheritage #noninvasivemethod

Keywords: laser cleaning, artifact restoration, non-invasive, conservation, cultural heritage

Long-tail phrases: laser cleaning for art restoration, non-invasive artifact cleaning, preserving cultural heritage objects

Challenges in adapting laser cleaning technology for different types of artifacts

1. Material compatibility:

- Not all materials react the same way to laser cleaning. Some materials may be more sensitive to heat or light, leading to potential damage during the cleaning process.

- It is important to test the compatibility of the artifact material with the laser cleaning technology before proceeding with the cleaning process.

2. Surface sensitivity:

- Some artifacts have highly sensitive surfaces that may be easily damaged by the intense heat generated by laser cleaning.

- Special care must be taken to adjust the laser parameters to ensure that the cleaning process is gentle enough to avoid surface damage.

3. Contaminant removal:

- Not all contaminants can be effectively removed using laser cleaning technology. Some stubborn stains or coatings may require alternative cleaning methods.

- It is important to assess the type and extent of contamination on the artifact before deciding on the most appropriate cleaning approach.

4. Operator training:

- Proper training is essential for operators using laser cleaning technology to ensure that artifacts are cleaned safely and effectively.

- Operators must be familiar with the specific requirements of each artifact and be able to adjust the laser parameters accordingly.

In conclusion, adapting laser cleaning technology for different types of artifacts requires careful consideration of material compatibility, surface sensitivity, contaminant removal, and operator training. By addressing these challenges, conservators can effectively utilize laser cleaning technology to preserve and restore cultural artifacts.

Keywords:

Laser cleaning technology, artifacts, conservation, restoration, material compatibility, surface sensitivity, contaminant removal, operator training

Long-tail phrases:

Challenges in adapting laser cleaning technology for delicate artifacts, Laser cleaning technology for cultural heritage preservation, Effective use of laser cleaning technology in artifact restoration

#laser #cleaning #technology #artifacts #conservation #restoration #material #compatibility #surface #sensitivity #contaminant #removal #operator #training, laser cleaning technology, artifacts, conservation, restoration, material compatibility, surface sensitivity, contaminant removal, operator training, Challenges in adapting laser cleaning technology for delicate artifacts, Laser cleaning technology for cultural heritage preservation, Effective use of laser cleaning technology in artifact restoration.

The role of laser cleaning in the restoration of archaeological finds

🔍 Jednym z głównych zastosowań laserowego czyszczenia w archeologii jest usuwanie osadów zabytków, które są narażone na degradację i zniszczenie. Laser pozwala na precyzyjne usunięcie warstw brudu i korozji, przywracając przedmiotom ich pierwotny wygląd i kształt.

🔍 Innym ważnym zastosowaniem laserowego czyszczenia jest usuwanie graffiti i innych zanieczyszczeń z powierzchni zabytków, które mogą być szkodliwe dla ich długotrwałego zachowania. Laser pozwala na skuteczne usunięcie niepożądanych elementów, nie niszcząc przy tym struktury ani powierzchni przedmiotów.

🔍 Laserowe czyszczenie jest również wykorzystywane do usuwania farb i innych substancji, które zostały nałożone na zabytki w celu ich ochrony lub ozdobienia. Dzięki precyzyjnemu działaniu lasera możliwe jest usunięcie tych substancji bez uszkodzenia oryginalnej powierzchni przedmiotów.

Warto podkreślić, że laserowe czyszczenie jest nie tylko skuteczną, ale także bezpieczną metodą konserwacji zabytków archeologicznych. Dzięki precyzyjnemu sterowaniu parametrami lasera możliwe jest minimalizowanie ryzyka uszkodzenia przedmiotów, co jest szczególnie istotne w przypadku delikatnych i kruchych materiałów.

Laserowe czyszczenie ma również wiele zalet w porównaniu z tradycyjnymi metodami konserwacji, takimi jak chemiczne oczyszczanie czy mechaniczne usuwanie zanieczyszczeń. Laser pozwala na precyzyjne i kontrolowane usunięcie zanieczyszczeń, co przekłada się na lepszą jakość i trwałość zabytków.

Wnioskiem z powyższego jest to, że laserowe czyszczenie odgrywa kluczową rolę w procesie restauracji zabytków archeologicznych, umożliwiając skuteczne i bezpieczne usuwanie zanieczyszczeń oraz przywracanie przedmiotom ich pierwotnego wyglądu i wartości historycznej.

hashtagi: #archeologia #restauracja #laseroweczyszczenie

słowa kluczowe: konserwacja, zabytki, artefakty, czyszczenie, restauracja

frazy kluczowe: metody konserwacji zabytków, laserowe czyszczenie w archeologii, precyzyjne usuwanie zanieczyszczeń.